Automated robotic arms play a significant role in industrial automation production and are the most widely applied type of automated mechanical device in the field of robotics. They enable the full automation of tasks that were previously performed manually. However, they all rely on a control system to send commands for motion control, enabling them to perform trajectory movements and precise positioning along points and lines in three-dimensional space. An automated robotic arm equipped with a mechanical hand control system akin to a brain can move rhythmically and flexibly in all directions, seemingly “seeing” objects and performing tasks such as grasping and transporting them.

Based on follow-up observations of customers, since manufacturing companies began using dedicated control systems on robotic arm equipment, production line efficiency has directly increased by 20%, helping businesses reduce costs and improve efficiency. This has effectively achieved the efficient automation transformation of “replacing humans with machines” in CNC workshop processing scenarioses.

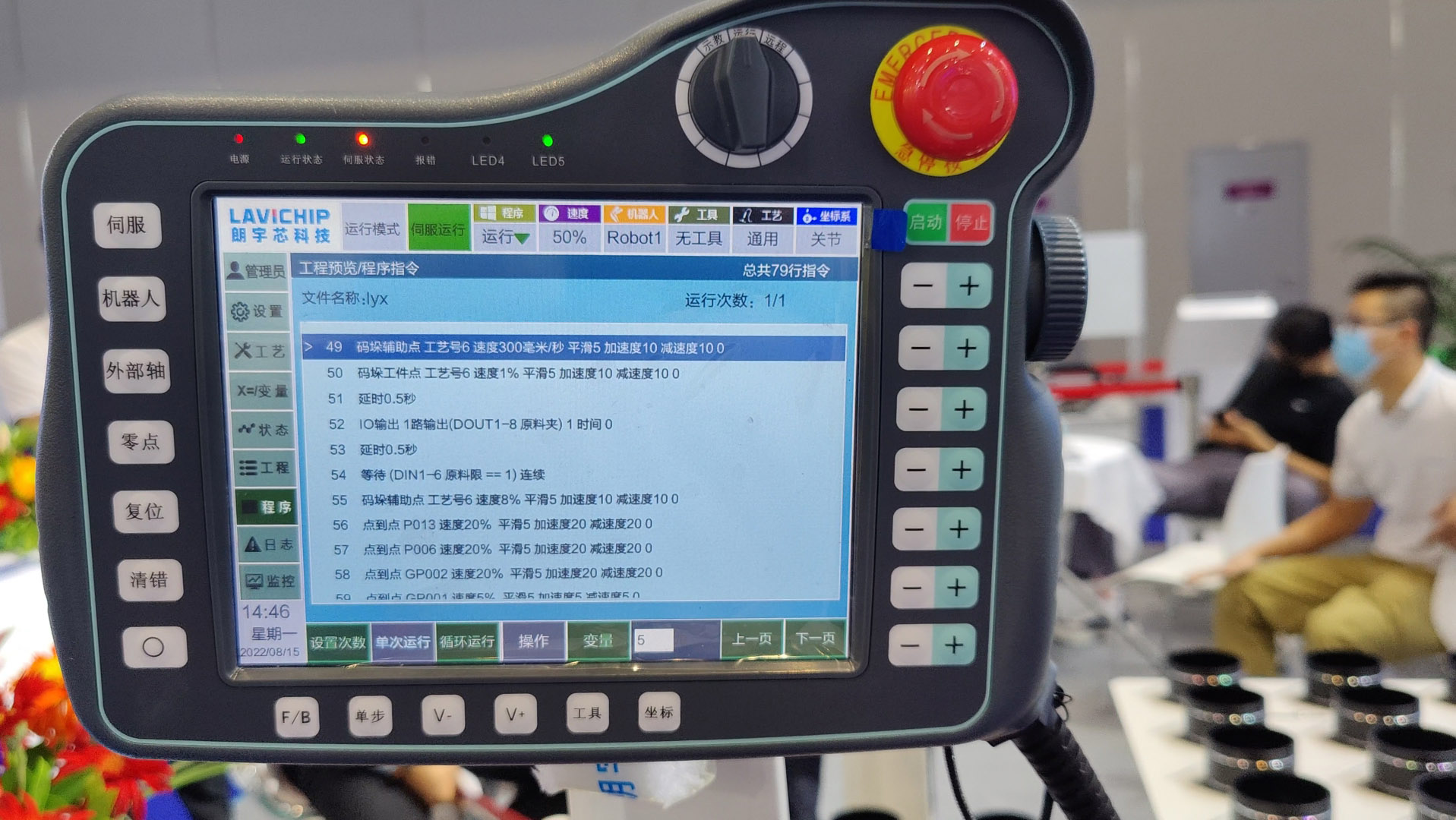

In fact, as a professional manufacturer specializing in the design and production of robotic arm control systems, control technology is at the core. Lavichip has embarked on a path of continuously developing leading-edge industrial automation control system products for the industry, promoting domestic substitution for imports, and achieving a leading domestic technological advantage.